Efficient Asset management services is a crucial focus area for most process industries, given the significant capital investments, as well as the criticality of those assets for production continuity and plant uptime.

An effective asset management services needs a solid foundation, and a good starting point is establishing a good clean asset register. The asset register would have multiple data points such as asset number, asset name, equipment number, location, and so on.

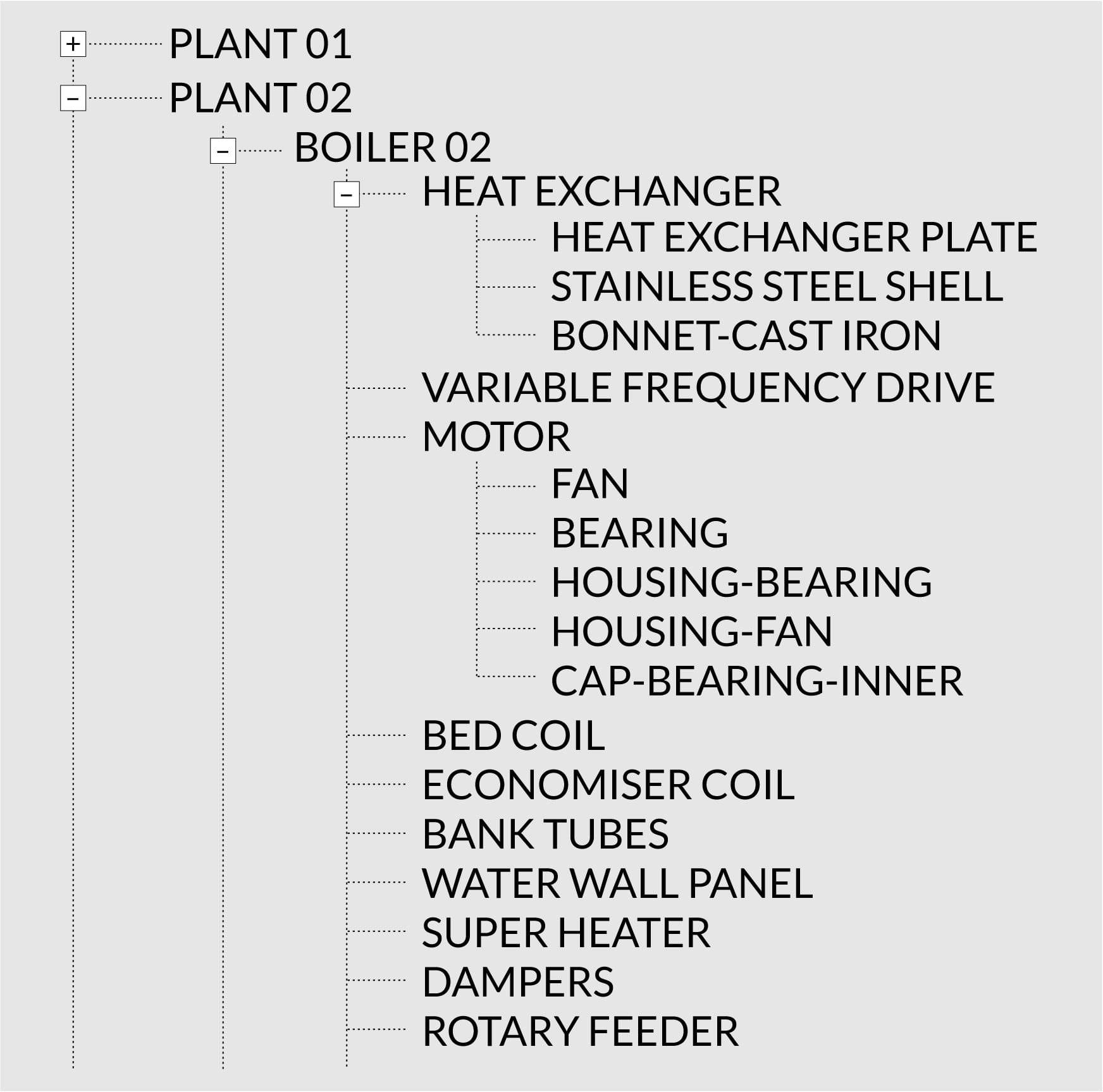

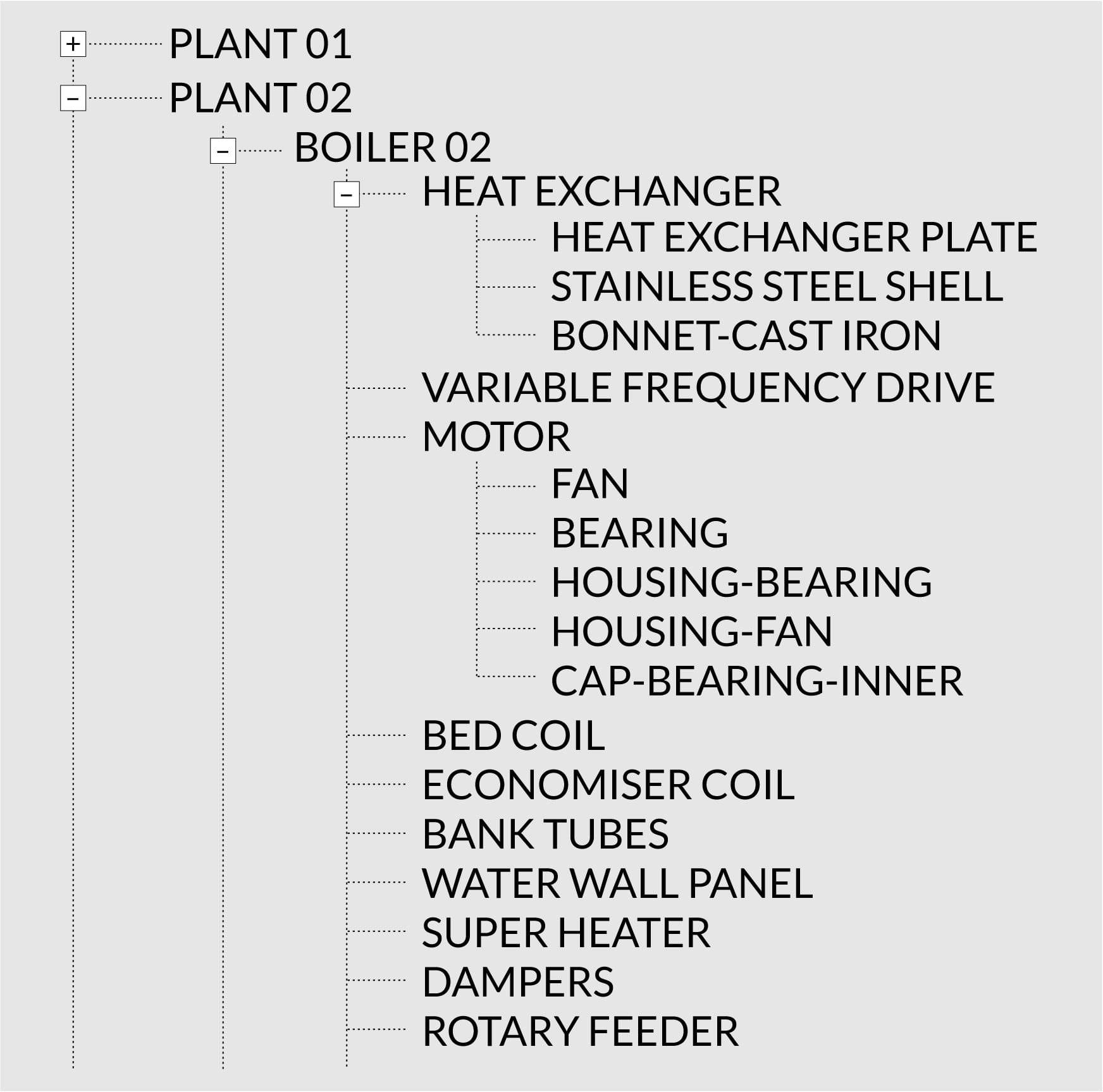

Most companies implement a hierarchical asset management system, as the ease of use is much better and this same hierarchy can also be integrated into the EAM or CMMS system.

Beyond the walk-downs, the next phase of support involves the creation of Asset BOMs, so maintenance teams know what spares are required for each equipment and system. The Equipment BOMs are typically also cross-referenced to the ERP/EAM (SAP, Oracle, JDE, Maximo, or other) material master, so the maintenance and supply chain teams can leverage the data to build out their programs.

We also provided managed solutions for connected maintenance, leveraging proven IIOT platforms, along with the resources needed to monitor and maintain the system. In most cases, clients struggle with multiple systems as well as a lack of internal bandwidth to run a connected maintenance program, which is where our solutions prove to be very useful.

A well-rounded asset integrity & liabilities management program improves operational efficiency, optimizes resources, reduces risks, improves uptime and maximizes ROI on asset investments. The data and analytics from the asset management system should help the organization make better decisions and plan for the future.

Beyond the walk-downs, the next phase of support involves the creation of Asset BOMs, so maintenance teams know what spares are required for each equipment and system. The Equipment BOMs are typically also cross-referenced to the ERP/EAM (SAP, Oracle, JDE, Maximo, or other) material master, so the maintenance and supply chain teams can leverage the data to build out their programs.

We also provided managed solutions for connected maintenance, leveraging proven IIOT platforms, along with the resources needed to monitor and maintain the system. In most cases, clients struggle with multiple systems as well as a lack of internal bandwidth to run a connected maintenance program, which is where our solutions prove to be very useful.

A well-rounded asset integrity & liabilities management program improves operational efficiency, optimizes resources, reduces risks, improves uptime and maximizes ROI on asset investments. The data and analytics from the asset management system should help the organization make better decisions and plan for the future.

We support clients in establishing a good reliable asset register and often do onsite plant walk-downs to collect the required information. We have an integrated well-oiled mechanism to do this, in a blended onsite-offsite model, so that the process is quick and efficient. If required, we also redline the client P&IDs and update the CAD drawings, based on as-built conditions.

Our Asset Management Services:

The primary objective to have a Spare Parts Interchangeability Record (SPIR), is to support organizations on the inventory level needed. Some of the answers program and project managers will seek are:

Read More about SPIR services

Often organizations are in situations where – a) data does not match with the inventory in a warehouse, b) stakeholders unaware of items in the warehouse, c) disorganized inventory, and these situations cause – decreased wrench time, bad/inaccurate maintenance schedules. Uniquely positioned as an organization with – engineering, MDM, and Enterprise Asset Management expertise, we help resolve the differences between assets, inventory, and digital data.

Read More about Plant Walkdown