- September 21, 2022

- OptimizeMRO

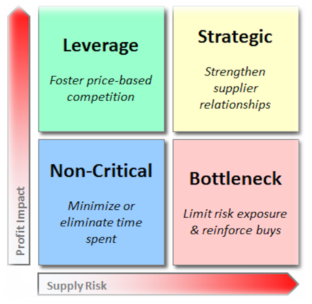

Most companies interact every day with a wide range of vendors. In this series, we have looked at three main categories of these vendors.

- Non-Critical Suppliers – If we can avoid spending time on high-volume, low-spend items, procurement can reduce costs. Our time and efforts are more expensive than the actual cost of these purchases.

- Bottleneck Suppliers – Procurement can reduce costs by regaining negotiating leverage from these suppliers.

- Leverage Suppliers – By fully utilizing our superior negotiating position to reduce prices, procurement may reduce costs.

Most of our vendors fall under these three groups when taken as a whole. The last group is much smaller than the others, but it is far more crucial. We will evaluate our strategic supplier today. The largest point of supply risk and profit effect is where these suppliers are in the upper right-hand corner of our Kraljic matrix (shown below for the final time in this series).

- Our companies are primarily shaped by the goods we purchase from these vendors. These vendors are crucial to the way we conduct business and the product we provide to our own clients.

- The market is naturally limited in supply. These items are difficult to find from vendors, and there will be a significant difference in what is offered. Supplier replacement will not be “plug and play.”

- Here, relationships may survive for years, even decades.

- In comparison to previous quadrants, this one has far more flexible and balanced points of bargaining power. Customers have few choices on the market and would find it difficult to switch to a rival offering. Suppliers frequently cannot take the chance of losing high-value clients. We must adjust our thinking away from thinking in terms of leverage (or a lack thereof) and instead concentrate on creating a relationship.

- Include suppliers in business operations. For instance, educate their staff on the procedures used by your team and produce ideas for improving their support of any inadequacies. Where in your workflow may they be more effectively implemented to increase process efficiency?

- Create collaborative alliances. A further investment in joint R&D (Research & Development) for product redesign or new service offerings will take an already important product and tailor it to your organization’s specific use while further orienting the supplier to better meet your needs. Your organization has a significant investment in the products these suppliers offer.

- Over shorter time frames, we frequently lose interest in long-term partnerships. Why check up on a supplier every month if they are producing regularly after all, they have been a supplier for decade, right?

- Many companies fall into this slow-moving trap. Consider the parable of the boiling frog. A frog will jump away when placed in boiling water, but it will not react if placed in cold water that is gradually raised in temperature. In the end, small problems that develop gradually turn into large ones that all too frequently go unnoticed until it is too late.

- Keep a close eye on your KPIs (Key Performance Indicators) and SLAs. The time is now to examine your supplier’s commitments and make sure they are being met. If you have not created any KPIs or monitoring procedures, think about the metrics that determine success or failure and how procurement can make sure a supplier is staying on course.

- Be stern about arriving at planned times. Years into these lengthy partnerships, quarterly assessments sometimes get postponed, cut short, or omitted completely. Stop it from happening. Likewise, follow the agenda even if it seems “done to death” after a while: The purpose of these meetings is to evaluate today’s performance, not to reminisce about the good old days.

- It is too simple to evaluate suppliers based on how well they provide products. This makes sense for certain other quadrants, but not for suppliers in the Strategic supplier quadrant. The operations of these vital suppliers should be considered during procurement.

- Be familiar with their BC/DR plan and their risk tolerance. Your company spends a lot of money ensuring that operations are not disrupted in the event of a calamity. Can your provider, though, make the same claim? Strategic supplier are a crucial component in a chain since a chain is only as strong as its weakest link. With suppliers, go through your business continuity and disaster recovery procedures. If your firm is significantly stronger in this area, attempt to assist the supplier in updating policy and procedure using your own resources.

- Recognize how your essential product fits inside the supplier’s portfolio. Certainly, purchasing this item is essential for you. But is selling important for your supplier in the same way? Do they intend to adjust better serve the market at the expense of your company? Are they shifting their focus away from your product and fully onto another? If any of these scenarios materializes, we may work with our companies to set up our own operations to either adapt to these changes or start the search for a successor. But if we do not anticipate this transformation, we cannot do either given the significant effect these items have.

Most of the cost-cutting tactics we have spoken about up to this point are short- to medium-term in nature. However, effects on this quadrant might have a long-term effect on our businesses.

Strategic Supplier Relationships

These four vendors all have a few significant things in common:

These are basic examples. This is your engine if you build automobiles. This CPU is what you need if you create computers. If you are Kenny G, these are the noises coming from that sax into your neighborhood elevator or the playlist on the weather channel.

The subject area knowledge possessed by these vendors’ teams plays a significant role in the items we purchase from them. No matter how skilled our procurement staff is, we cannot match the insights that these vendors can offer. Instead, we ought to use this SME as much as we can.

Promote Integration with Suppliers

Monitor the Relationship

Move Beyond the End Point

Talk to one of our Procurement Specialists today.